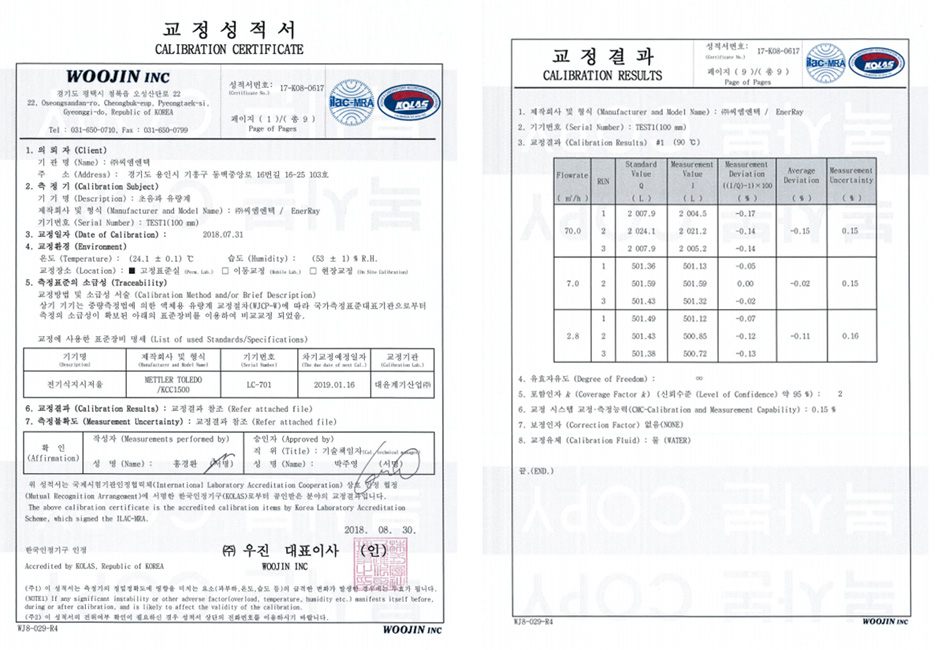

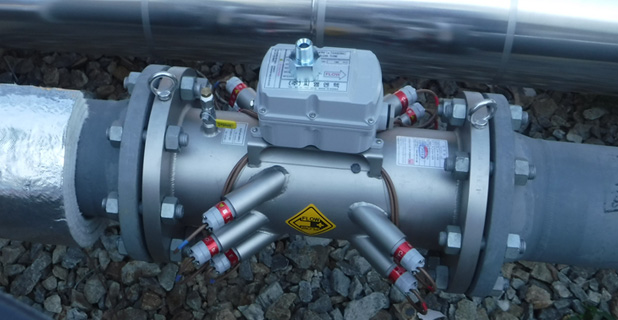

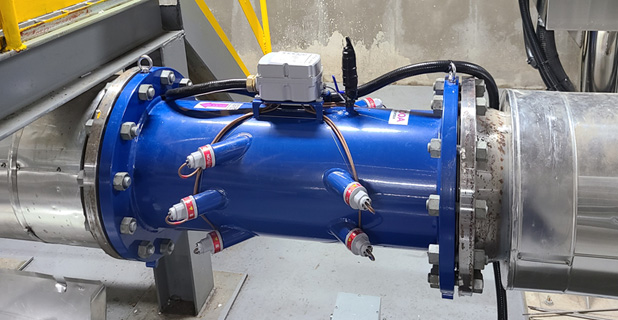

Combination Measuring Tube

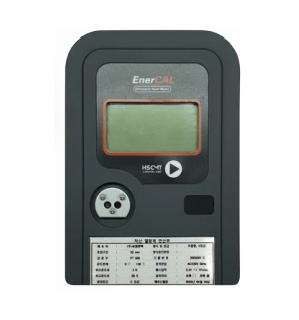

Flow Measuring Unit

Caluculation Unit

All-In-One Measuring Tube

All-In-One With Flow Measuring Unit + Caluculation Unit

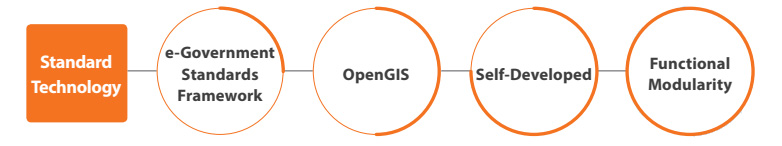

A system that maintains and manages the heat pipe network efficiently and sustainably by collecting and analyzing the data of the heat pipe network using ICT (information and communication) technology to support decision-making

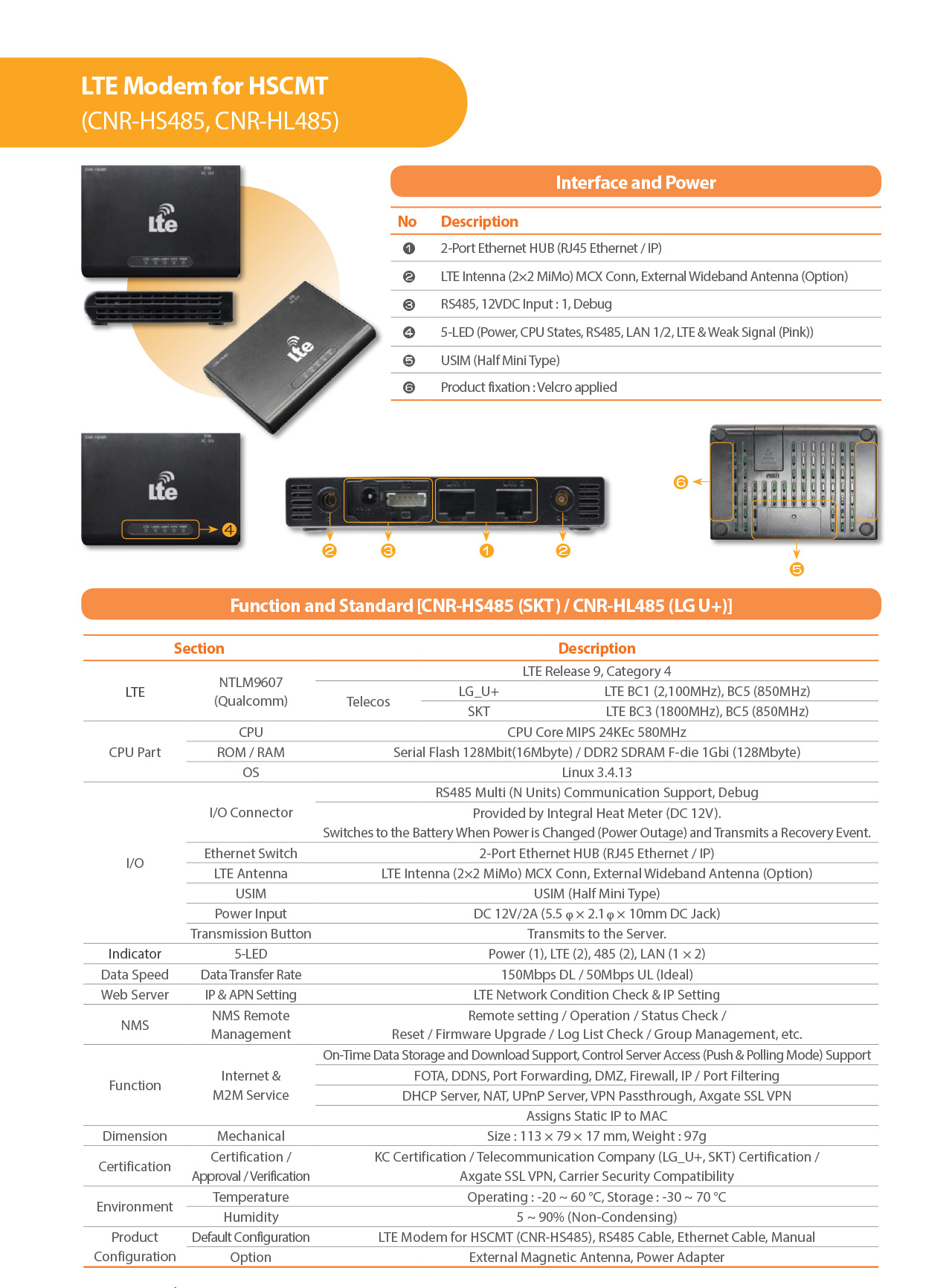

Ultrasonic flow meters are optimized for measuring high-temperature fluids/flow rates up to 200℃, which are optimized for measuring the main feedwater flow rate of power plants, district heating heat supply, etc.

· Accurate measurement is possible even at high temperature and high pressure through the application of titanium sensor.

· It is possible to accurately calculate the flow rate using the multi-path measurement method 3-5 paths double integration algorithm.

· Even if the flow rate distribution changes complexly, accurate flow rate measurement is possible without the influence of the diagonal component and the rotational component.

· Multi-path measurement using ultrasonic sensors ensures high precision even at short straight pipes (5D at the upstream end / 2D at the downstream).

· It can be non-stopping constructed in the field, so it can be install transducer and maintain under pressure without process shut-down (hot-tap)

· Maintenance costs are low with 100% domestic technology.

· Hot Tapping Maintenance : Possible to maintain under pressure without process shut-down (no need by-pass line)

· Data log : USB memory download function, instantaneous heat, integrated heat, pressure, etc. (300,000 Data)

· Power failure monitoring function (on/off record storage), power failure return processing function, partially filled pipes identification function, automatic signal control function, automatic zero adjustment function

· Graph the fluid flow inside the pipe (Velocity Profile)

Flange Type

Flange Type

Flange Type

Direct Non-stopping Installation Type (Hot-Tapping)