Combination Measuring Tube

Flow Measuring Unit

Caluculation Unit

All-In-One Measuring Tube

All-In-One With Flow Measuring Unit + Caluculation Unit

EnerRay ultrasonic heat meters are optimized for regional or centralized heating, cooling, and heating-cooling combined systems. They are divided into all-in-one heat meters with built-in calculation unit, including temperature sensors and calculation functions; ultra-precision ultrasonic heat meters, which calculate accurate energy consumption based on flow rate and temperature difference; and combination products, which operate separately from the calculation unit.

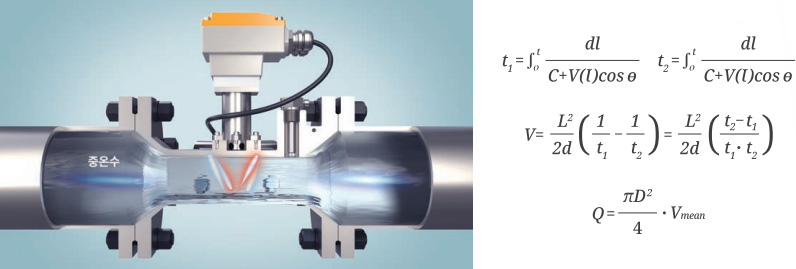

EnerRay flow measurement unit measures the flow velocity and flow rate using the digital ultrasonic propagation time difference. The ultrasonic propagation time difference uses the principle that the speed of the fluid changes the propagation speed and direction of ultrasonic pulses. At the flow velocity of each position, the time when the ultrasonic pulse is transmitted in the same direction as the fluid flow is faster than when it is transmitted in the reverse direction.

| Performance | Class 2 |

|---|---|

| Use | For medium hot water (0 ~ 130) ℃ |

| Environment | Rating C |

| Magnification | 25x / 100x (flow ratio) |

| Application | Supply and return lines of medium and hot water / Cold water cooling (Flange: DIN16) |

| Applied standard | integral heat meters technical standard (National KATS) - cold water and cooling line, OIML R-75, EN1434 |

· Almost no pressure loss and a wide flow measurement range

- World-class 100:1 flow ratio (Class 2): EnerRayH, EnerRayⅡ

- 25:1 flow ratio designed for general use environments: EnerRay

· Requires short straight pipes at the rear end of the curved pipe (5D / 2D): Minimize flow effects with a special cross-sectional structure

· Provides LOP for communication modem installation and field noise blocking

· 1:1 compatible with mechanical flow measurement units

- Optimized structure that satisfies the minimum interplanar distance required by Korea District Heating Corporation (same as mechanical type)

· Integrated low measurement units, calculation units, and temperature sensors for excellent maintenance (all-in-one)

· Installed in the supply water to prevent transaction issues in case of mixed fluid in the heat exchanger due to a user facility failure

· Collect/analyzes heat pipe network data as a heat pipe network solution (E-Navi).

· Provides compatibility for connection with all calculation unit products sold in Korea .

· Possible to change the installation location depending on the usage environment by adopting a detachable controller structure.

Medium hot water heat transaction (e.g., district heating), remote meter reading, energy measurement, industrial heat management, and high-temperature flow measurement